FREQUENCY RESPONSE:

The Key Specification that's often overlooked

One may wonder if this discussion has anything to do at all with force and /or torque sensors, however with little patience, not only some ambiguity will be removed, but also some very decisive eye-openers will be revealed when considering a sensor for an application.

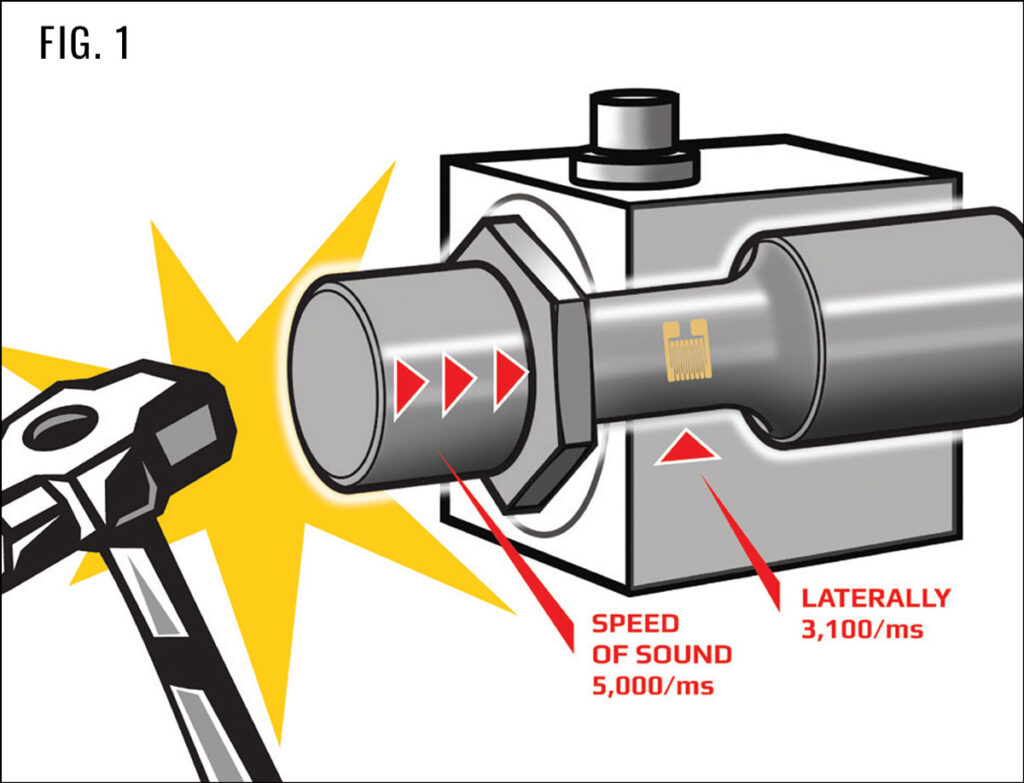

The schematic (FIG. 1) is a simplified yet very accurate representation to what happens in a sensor, from the moment an event (e.g. impact force) is applied to the sensor till this event shows up on an indicator.

The event (the impact) causes a stress wave that travels in the sensor at the speed of sound longitudinally (at 5000 m/s) and laterally (at 3100 m/s) to reach strain gauge locations.

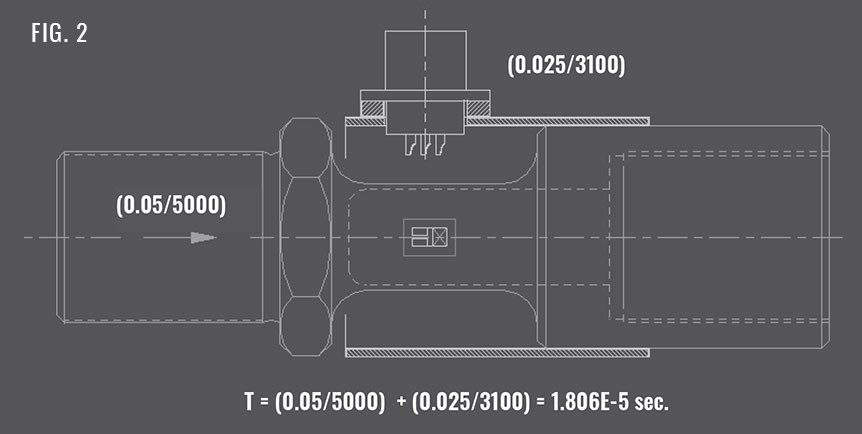

Assuming a sensor 10cm long, and 5cm diameter, gauges are in the middle of the sensor, then time “T” for stress wave (event) to reach gauges;

T=(0.05/5000) + (0.025/3200) = 1.806E-5 sec. (FIG 2)

i.e. this sensor can respond to a signal frequency 1/T = 55,357 Hz

For all practical purposes, any simple sensor (a Wheatstone bridge of strain gauges on a piece of metal) can translate the mechanical energy of an event into proportional electrical energy in almost no time

NEED A QUOTE?

We love helping our clients excel. We are happy to discuss your sensor requirements and provide ideas on how you can become more competitive, productive and profitable with SDT products.

Need a Quote?

We love helping our clients excel. We are happy to discuss your sensor requirements and provide ideas on how you can become more competitive, productive and profitable with SDT products.